Description

The Syvecs S12 has been designed to withstand some of the toughest of condition and still provide enough I/O to run a V12 engine fully sequentially for a life time.

Syvecs S12 Full Specification:

Features

- Fulling Control

- Ignition Control

- Boost Control – Open Loop or Closed Loop

- Gear Shift Set-up – Auto or Manual

- Gear Cut – Open Loop or Closed loop

- Gear Blip – Open loop or Closed loop

- Throttle Jacker Control

- Throttle Bypass Value control

- Limp Setup and Sensor Warnings

- Anti Lag System

- Nitrous Control – Wet or Dry Control

- Traction Control

- Flex Fuel

- Full Knock Control – Advance and Retard, Fully

- Adjustable Starting Strategies

- Idle Control – Closed or Open Loop

- Idle stepper control

- Limiters

- Launch Control – Open Loop or Closed loop

- Drive by wire

- Variable Valve timing – Closed or Open Loop

- GDI / Direct Injection Control

- DI + Port Injection Control

- Custom Maps Options

- Cruise Control

- SENT Protocol Sensor Support

- LinBus Support

- OBD2 Protocol Support on S7 Range

- Supercharger Bypass Valve control

- Differential Control

- Torque Estimation and Limitation – DCT Control

- Adjustable Output Functions

- Fuel Consumption monitoring

- Engine Use Restriction

- Output Testing

- Adjustable Pin Assignments

- Datastreams – Configurable Custom CAN or Custom

- RS232 Map Switching – Live and up to 24 options

- Onboard Datalogging

- GPS Receiver Support

- RI45 Ethernet Connection

Inputs

- 32 x General purpose inputs

- 4 x Knock inputs

- 2 x NTK wide band Lambda interfaces

- 2 x K-type thermocouple interfaces

Outputs

- 50 user configurable general purpose Pulse Width Modulated power outputs, including:

- 12x Ignition Coil outputs – IGBT (Coil Direct) or TTL (ignitor)

- 24x Fuel injector outputs

- 8x PWM Outputs

- 3x full bridges also configurable as 6 half bridges or 6 PWMs

- Up to 20A output per Full Bridge (DbW & HDP-5)

Interfaces

- 100 MHz full duplex Ethernet for connection to PC for programming and data download

- 3x Can 2.0B interfaces

- RS232 serial interface

Memory

- Up to 128MB flash logging memory

- Fast download – less than 30 seconds via Ethernet

- Time/Date stamped data via real time clock

Power Supply

- 6 to 26v input voltage range with reverse polarity protection

- 2x regulated 5V sensor supply outputs with protection

- Software configurable sensor (5v to 12v) sensor supply output

- Unregulated sensor supply output which tracks the ECU supply voltage

- 5 Separately protected sensor and communication ground inputs

Physical

- Twin split automotive connector totalling 121 pins

- Anodised aluminium case

- Maximum dimensions including the connectors 178 x 160 x 45 mm

- Total mass is 670 grams

- Operating Temperature -25 to +95 C

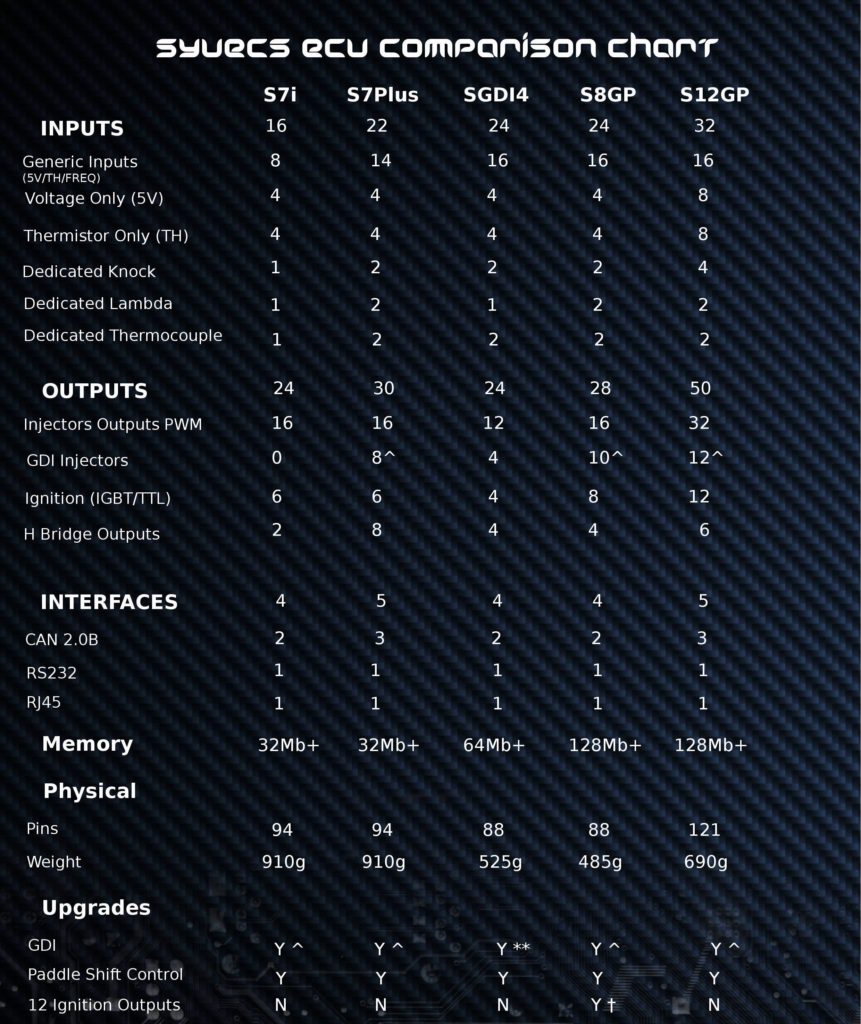

Unsure what model ECU is right for you?

Please see the Syvecs model comparison below which highlights all of the main differences of the various models of Syvecs ECU’s.

Here at Northampton Motorsport, we also offer a full wiring and fitting service as well as engine calibration on our in house Superflow AD30 2 wheel drive chassis dyno. For more information, please contact us and a member of our team would be happy to assist with your enquiry:

Contact UsAll ECU’s are configured to order so the lead times can vary. Estimated dispatch time within 10 working days.

Picture for illustration purposes only. Actual parts may differ slightly in appearance.